Khoom

Organic Fertilizer Manufacturing Production Line

KHOOM NTAUB NTAWV

Cov organic chiv ntau lawm yog siv los ua cov txheej txheem sib txawv fermented organic tshuaj rau hauv cov organic chiv.It adopts ib-kauj ruam molding tshuab.Tsiaj quav quav thiab cov khib nyiab ua liaj ua teb yog siv los ua cov khoom siv tseem ceeb, kev tsim cov kab mob organic chiv thiab ua kom tsis muaj menyuam siv cov tsiaj txhu thiab nqaij qaib.Nws yuav pab txhawb txoj kev loj hlob ntawm ecological kev ua liaj ua teb thiab ncig kev lag luam.

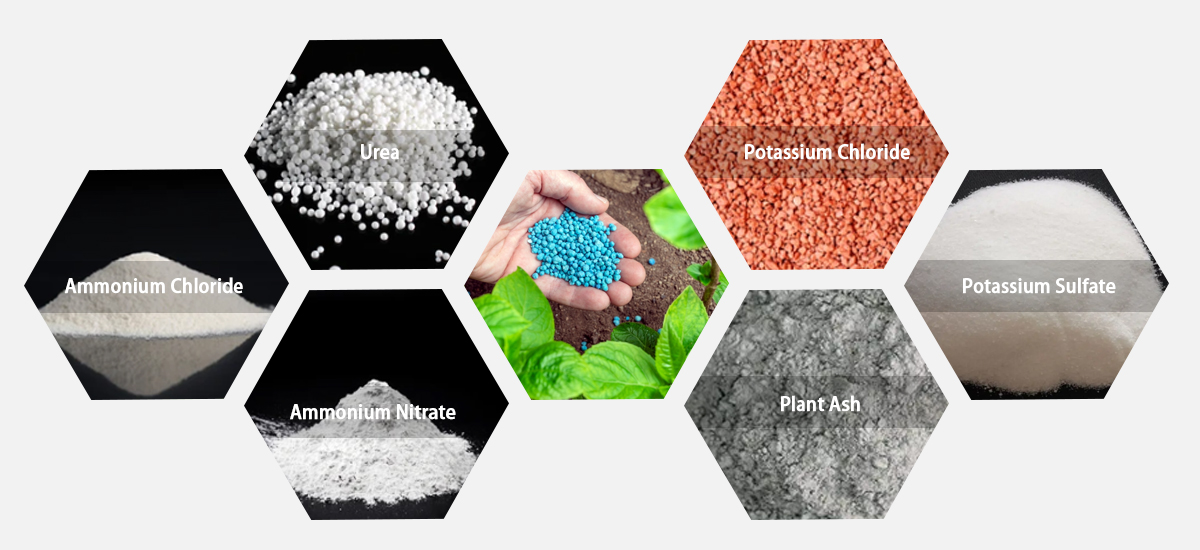

Raw khoom ntawm organic fertilizer manufacturing cog cog:

1. Agricultural pov tseg: Straw, dregs ntawm taum, paj rwb dregs, nplej bran, thiab lwm yam.

2. Tsiaj quav quav: sib tov ntawm nqaij qaib litter thiab tsiaj pov tseg, xws li cov khib nyiab ntawm slaughterhouse, ntses khw, tso zis thiab dung ntawm nyuj,

Npua, yaj, qaib, ducks, geese, tshis, thiab lwm yam.

3. Muaj pov tseg: Wine lees, vinegar residue, manioc pov tseg, qab zib scum, furfural residue, thiab lwm yam.

4. Cov khoom seem hauv tsev: cov khoom pov tseg, cov hauv paus hniav thiab nplooj ntawm cov zaub, thiab lwm yam.

5. Sludge: sludge ntawm tus dej, dej phwj tuaj, thiab lwm yam.

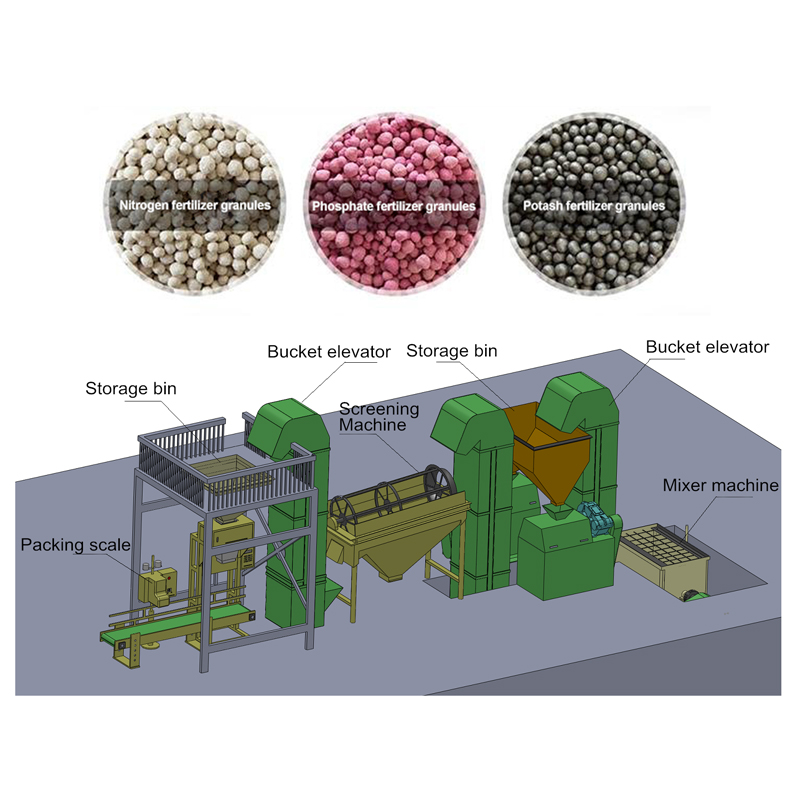

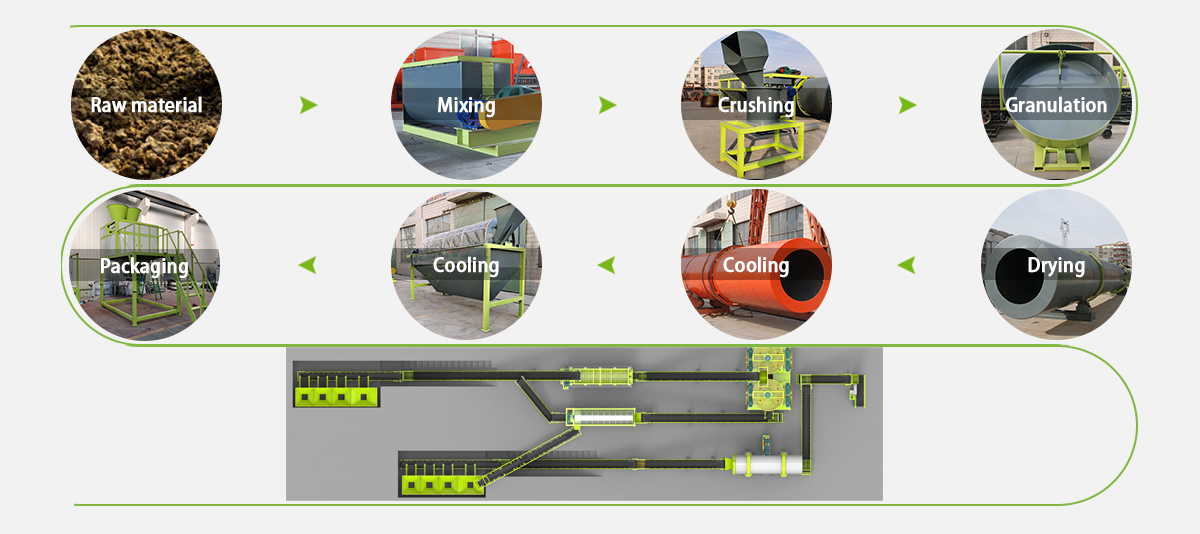

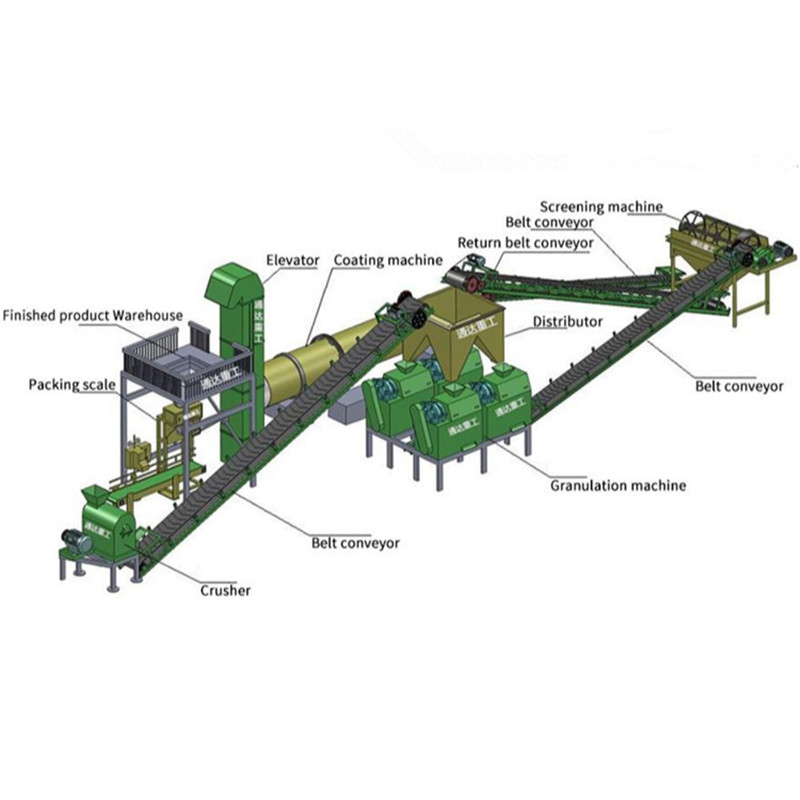

Tag nrho cov organic chiv ntau lawm suav nrog cov tshuab hauv qab no: raw khoom fermentation → chiv crushing tshuab → chiv tov tshuab → chiv rotary nruas granulator → chiv teb nruas ziab / txias tshuab → chiv teb nruas txheej tshuab → chiv teb tshuaj ntsuam tshuab → chiv ntim tshuab → siv conveyor → thiab lwm yam khoom siv.

1.Organic cov ntaub ntawv fermentation txheej txheem plays lub hauv paus tab sis indispensable luag hauj lwm nyob rau hauv tag nrho cov chiv ntau lawm kab.Ob lub ntsiab ntawm cov compost turner yog dav siv los tig thiab sib tov cov compost thiab ceev cov fermentation ceev: tus kheej-propelled compost turner thiab hydraulic compost turner.

2.Crushing txheej txheem: Cov ntaub ntawv compost yuav tsum yog av ua ntej txheej txheem granulating.Tab sis peb tuaj yeem tso tawm cov txheej txheem crushing thaum cov khoom siv compost zoo txaus.Vertical saw crusher thiab ob-ncej kab rov tav crusher, ob hom crushing tshuab tuaj yeem siv los txhuam cov pob zeb chiv chiv raw cov ntaub ntawv.

3.Cov txheej txheem sib tov, ob hom kev sib xyaw tshuab yog siv los sib xyaw cov ntaub ntawv raw hauv cov kab ntau lawm: Kab rov tav tov khoom thiab ntsug tov khoom.

4. Kev ziab kom qhuav.Thaum chiv granulating, cov dej noo ntawm cov khoom siv raw yuav tsum tsawg dua 25%, yog li peb yuav tsum qhuav cov ntaub ntawv raw yog tias cov dej noo ntau dua 25%.Rotary nruas drying tshuab yog tsuas yog siv rau ziab cov chiv nrog ib qho degree ntawm cov av noo thiab particle loj.

5.Fertilizer granulator txheej txheem.Cov txheej txheem granulating yog qhov tseem ceeb hauv cov kab ntau lawm, yog li peb xaiv cov qauv tsim nyog ntawm cov chiv granulator raws li cov neeg siv khoom xav tau. Cov khoom siv granulator xaiv: Organic chiv ua ke granulator, organic chiv tshwj xeeb granulator, khub yob extrusion granulator, disc granulator, ca zaj duab xis. granulator, bio organic chiv spherical granulator, nruas granulator, round tossing tshuab, thiab lwm yam .;Cov ntaub ntawv siv xws li: qaib quav, nyuj dung, kaolin, thiab lwm yam.

6.Rotary nruas txias tshuab yog siv rau txias chiv kom cov chiv muaj zog.

7.Screening txheej txheem: Rotary nruas tshuaj ntsuam tshuab yog siv los cais cov granules los ntawm cov khoom loj uas yuav tsum tau xa rov qab rau qhov thib ob crushing thiab granulating.Rotary nruas txheej tshuab yog siv los npog cov chiv thiab tiv thaiv cov chiv los ntawm kev sib txuas ua ke.

8.Cov txheej txheem kawg yog txheej txheem ntim khoom.Fertilizer ntim tshuab tuaj yeem ntim cov hnab ntim ntau npaum li cas thiab tau txais.Including electronic quantitative packaging scale.It kuj xav tau qee yam khoom siv rau kev sib txuas xws li siv conveyor, thoob of elevator, thiab lwm yam.

High ntau lawm efficiency:

Tag nrho cov txheej txheem yog kev ua haujlwm tsis siv neeg.Kev ua haujlwm yooj yim, tsuas yog ob tus neeg tuaj yeem ua haujlwm.

Tsawg tus nqi khiav lag luam thiab kev siv hluav taws xob tsawg:

Txhua yam tsiaj txhu tuaj yeem ua tiav.4 teev lom deodorization.Pov tseg tshav kub rov qab txuag hluav taws xob thiab kev tiv thaiv ib puag ncig.Haum rau cov liaj teb loj, nruab nrab thiab me.

Kev siv dav ntawm cov khoom tiav:

Kev ua liaj ua teb npua, nyuj ua liaj ua teb, thiab lwm yam.