Khoom

Nyuj Manure Organic Fertilizer Production Line

KHOOM NTAUB NTAWV

Khoom taw qhia

- Nyuj manure organic chiv ntau lawm kab yog ib tug ua tiav cov cuab yeej rau kev ua cov organic chiv nrog nyuj manure ua raw khoom.Nqaij nyuj tuaj yeem tso rau hauv cov khoom siv los ntawm lub tshuab ua nyuj quav los ntawm lub twj tso kua mis slurry.Tom qab lub cev qhuav dej, cov ntsiab lus dej tom qab kho yog li 40%.Nws tseem tuaj yeem sau nrog cov qoob loo xws li straw thiab nplej bran (muaj NPK).Tom qab ntawd nws yog txau nrog cov tshuaj tua kab mob lom neeg, 1KG cov kab mob cov kab mob sib xyaw nrog 20KG dej.Nws tuaj yeem ferment 1 tuj ntawm raw khoom thaum nws txav mus rau hauv cov khoom siv raw.Tig ib zaug txhua 1-2 hnub, feem ntau 7-10 hnub tuaj yeem decomposed tag nrho.

- Nyob rau hauv xyoo tas los no, cov pa phem ntawm cov tsiaj nyeg thiab nqaij qaib thiab cov zis thiab cov khoom seem ntawm cov tsiaj nyeg thiab nqaij qaib ua rau muaj teeb meem rau tib neeg kev noj qab haus huv.Cov pa phem los ntawm cov tsiaj nyeg thiab nqaij qaib ua liaj ua teb tau dhau los ua qhov tseem ceeb ntawm cov pa phem nyob rau hauv cov chaw nyob deb nroog ntawm Tuam Tshoj.Cov ntaub ntawv loj loj ntawm cov tsiaj txhu thiab cov nqaij qaib tsis tuaj yeem tsis quav ntsej.Yog tias tsis kho kom raug, nws yuav ua rau muaj kuab paug loj rau ib puag ncig.

- Piv txwv li, vim tsis muaj kev kho mob raws sij hawm ntawm cov tsiaj nyeg thiab nqaij qaib, cov dej saum npoo av, dej hauv av, av thiab huab cua yuav ua rau muaj kuab lom heev.Dab tsi yog qhov hnyav dua yog tias cov tsev tu me me tsuas yog tso cov nqaij nyuj dung ntawm ib sab ntawm txoj kev loj kom yooj yim rau kev thauj mus los, tsis tas siv txoj kev khaws cia.Vim tsis saib xyuas ntawm kev tswj, cua thiab nag, cov excrement ntws txhua qhov chaw.Cov xwm txheej zoo li no tsis haum rau cov kev cai ntawm kev tiv thaiv tsiaj txhu, tab sis kuj yuav muaj kev cuam tshuam rau tib neeg lub neej nyob ib puag ncig.

Lub ntsiab Technical Parameters

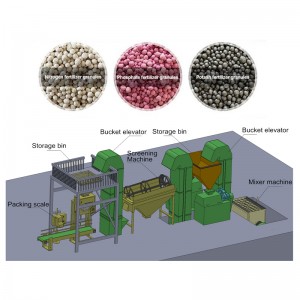

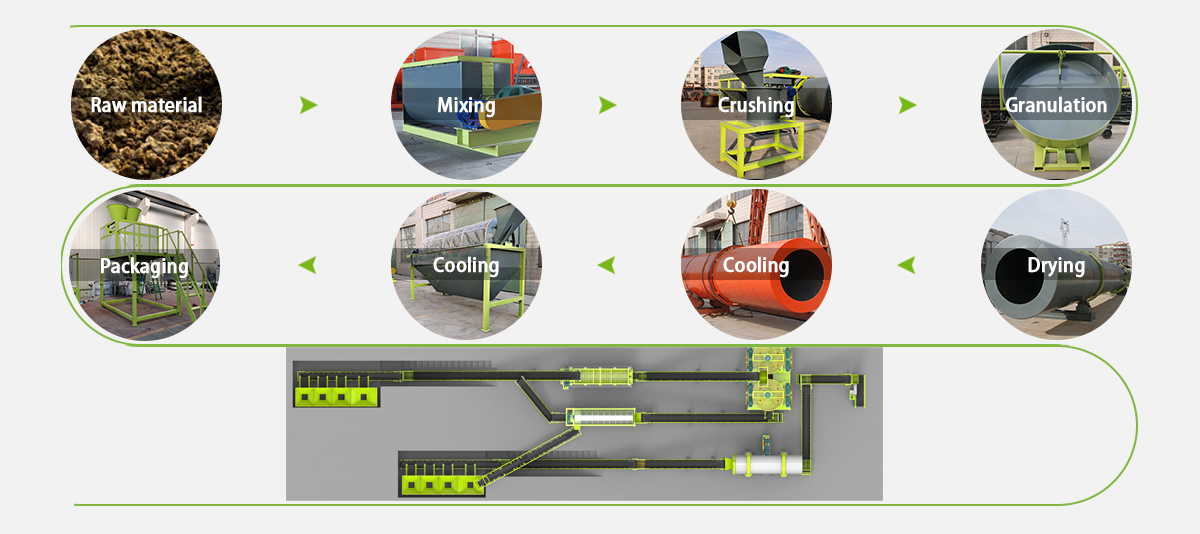

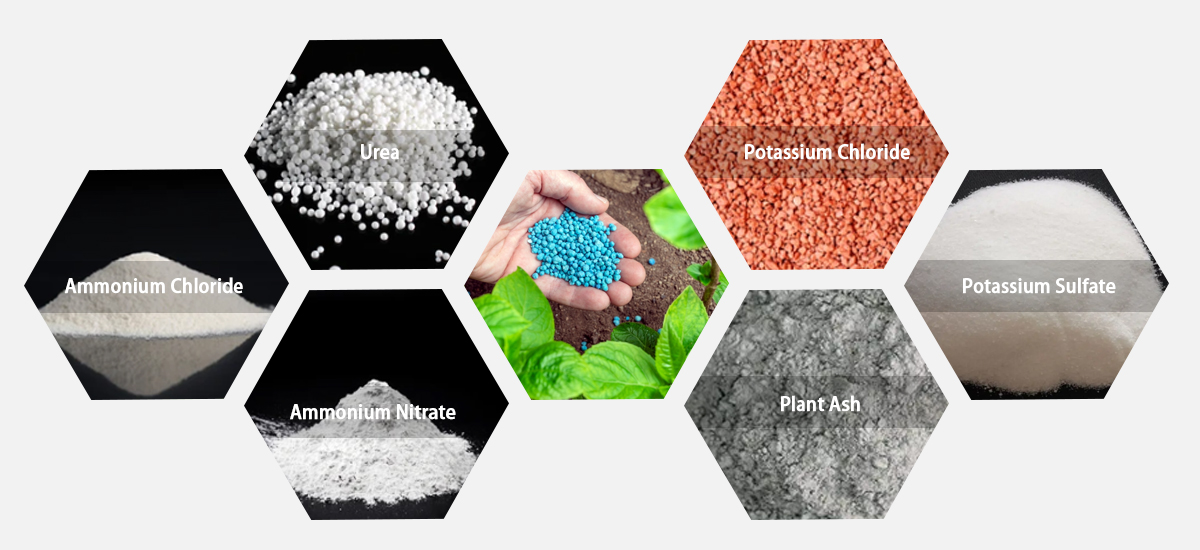

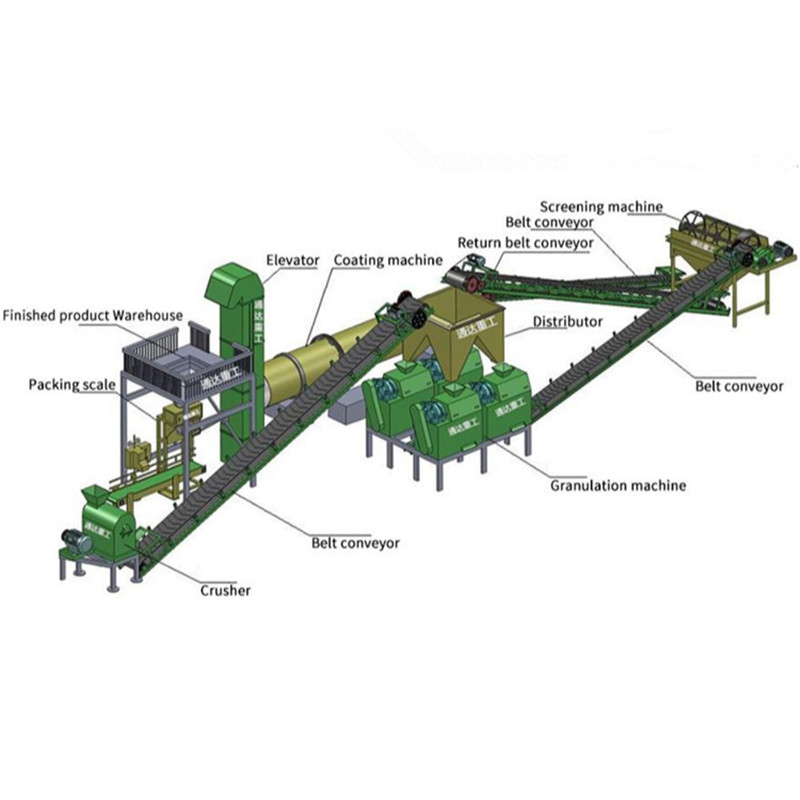

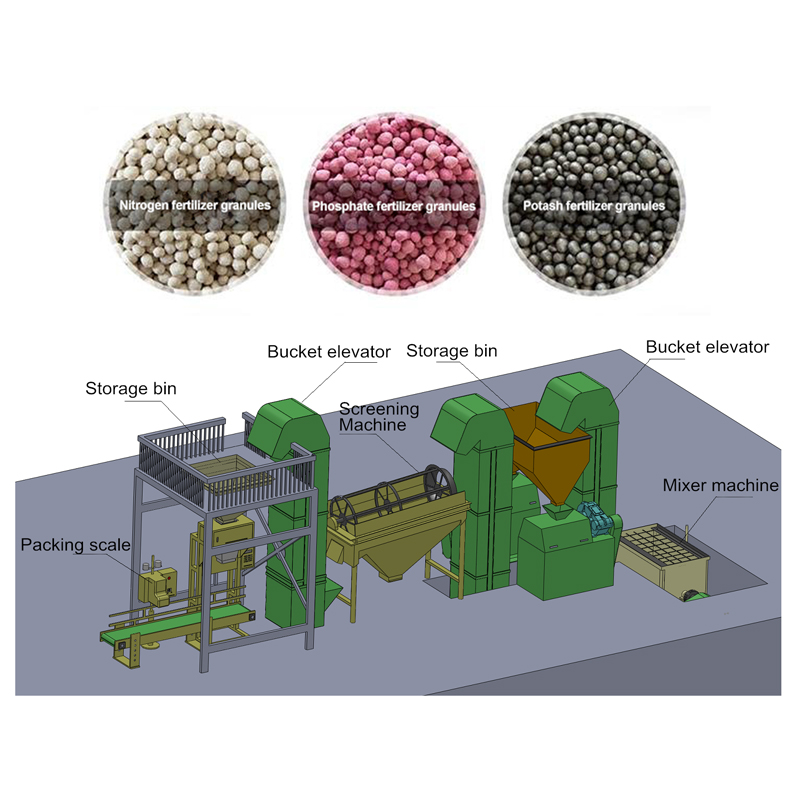

- Fermentation ntawm raw cov ntaub ntawv: nqaij qaib manure, npua quav, nyuj quav, biogas residue thiab lwm yam tsiaj manure yuav fermented los yog ua tiav nrog chiv-npaum raw cov ntaub ntawv nyob rau hauv ib tug tej yam kev faib ua feem (raws li kev ua lag luam xav tau thiab cov av xeem nyob rau hauv ntau qhov chaw).

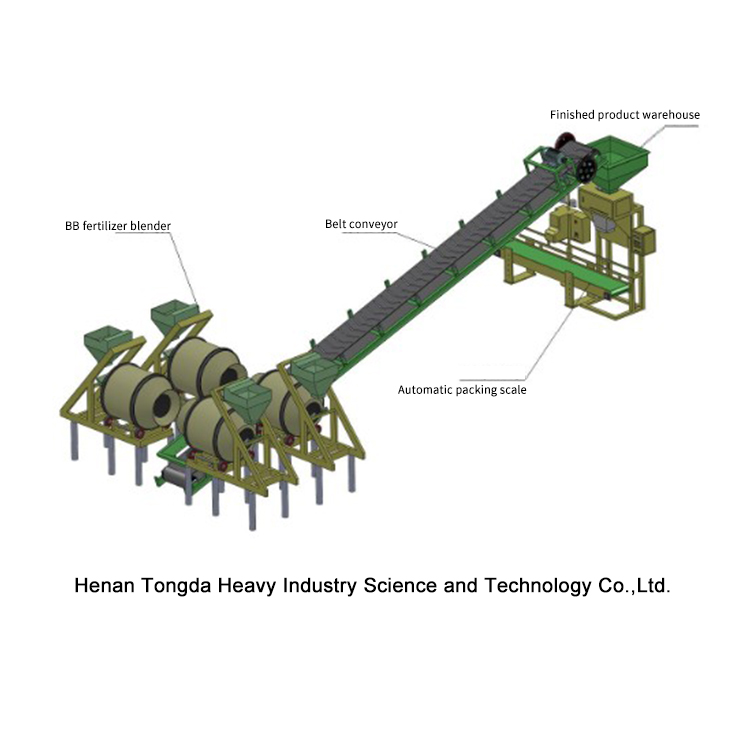

- Cov khoom sib xyaw: sib tov cov ntaub ntawv raw khoom sib npaug los txhim kho cov txiaj ntsig zoo ntawm tag nrho cov chiv granule.

- Khoom siv granulation: Pub cov khoom sib xyaw ua ke rau hauv granulator rau granulation (nruas granulator lossis extrusion granulator tuaj yeem siv tau).

- Particle drying: Lub granulator yog pub rau hauv lub tshuab ziab khaub ncaws, thiab cov dej noo uas muaj nyob rau hauv granule yog qhuav los ua kom lub zog ntawm granule thiab pab txhawb nws txoj kev khaws cia.

- Particle txias: Tom qab ziab, qhov kub ntawm cov chiv yog siab dhau thiab yooj yim rau agglomerate.Tom qab txias, nws yooj yim rau khaws thiab thauj hauv hnab.

- Particle Classification: Tom qab txias, cov khoom raug cais tawm.Cov khoom tsis tsim nyog yog crushed thiab rov granulated, thiab cov khoom tsim nyog raug tshuaj xyuas.

- Cov khoom tiav tiav: txheej cov khoom tsim nyog kom ua kom lub teeb ci thiab sib npaug ntawm cov khoom.

- Kev ntim cov khoom tiav: Cov khoom siv zaj duab xis-coated, piv txwv li cov khoom tiav, tau ntim thiab khaws cia rau hauv qhov chaw cua.

Cov yam ntxwv ua haujlwm

- Organic chiv ntau lawm kab khoom, compact txheej txheem layout, scientific thiab rational, advanced technology, zog txuag, noj txo, tsis muaj peb emissions, ruaj khov, txhim khu kev qha lag luam, yooj yim txij nkawm, dav adaptability ntawm raw cov ntaub ntawv.

- Organic compound fertilizer, bio-organic fertilizer, municipal sludge thiab domestic khib nyiab organic chiv, uas yog haum rau ntau yam proportions, tau sau lub domestic dawb paug thiab nyob rau theem ua nyob rau hauv Suav teb.

- Nqaij qaib manure yog lub teb chaws ib puag ncig kev tiv thaiv kev siv tshuab txhawb nqa qhov project, uas yog nplua nuj nyob rau hauv cov organic teeb meem, tuaj yeem muab cov as-ham uas xav tau rau cov qoob loo loj hlob, thiab tuaj yeem fertilize thiab txhim kho av.

- Muaj ntau ntau hom organic chiv, raw cov ntaub ntawv yog dav heev, thiab cov chiv kuj hloov sai heev.

Txoj cai ua haujlwm

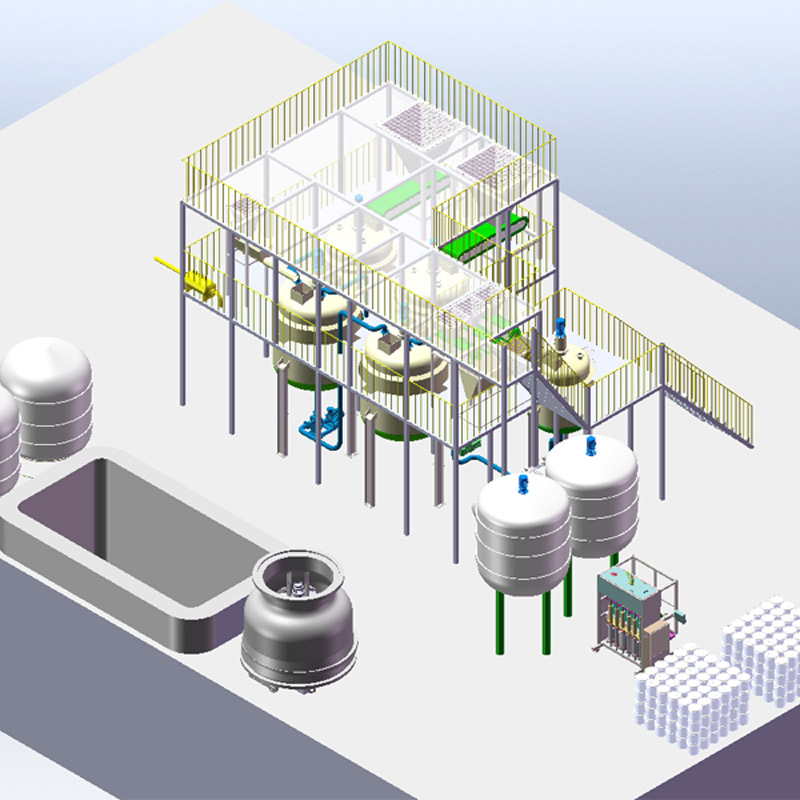

Organic chiv ntau lawm txheej txheem yog ze ze rau cov khoom configuration ntawm organic chiv ntau lawm kab.Feem ntau, cov cuab yeej ua tiav ntawm cov organic chiv ntau lawm muaj xws li fermentation system, drying system, deodorization thiab plua plav tshem tawm, kev sib tsoo system, cov khoom siv, kev sib xyaw ua ke, granulation system, cua txias thiab ziab, tshuaj ntsuam xyuas thiab cov khoom ntim tiav.

Hauv qab no yog cov lus piav qhia ntxaws ntxaws ntawm cov khoom yuav tsum tau ua ntawm txhua qhov txuas txuas hauv cov txheej txheem tsim cov organic chiv:

- Fermentation system ntawm cov txheej txheem organic chiv muaj xws li pub conveyor, lom deodorizer, tov khoom, proprietary lifting dumper thiab hluav taws xob tsis siv neeg tswj qhov system.

- Lub tshuab ziab khaub ncaws: Cov cuab yeej tseem ceeb ntawm lub tshuab ziab khaub ncaws muaj xws li siv lub tshuab ziab khaub ncaws, lub tshuab ziab khaub ncaws, cua txias, cua ntxuam ntxuam, qhov cub kub, thiab lwm yam.

- Deodorization thiab plua plav tshem tawm qhov system: Deodorization thiab plua plav tshem tawm qhov system yog tsim los ntawm chav tsev, plua plav tshem tawm chamber thiab lwm yam.Nkag mus rau Hnyav Kev Lag Luam muab kev kos duab dawb thiab kev qhia pub dawb rau cov neeg siv los tsim

- Crushing system: Lub crushing system muaj xws li ib tug tshiab semi-ntub khoom crusher tsim los ntawm Zhengzhou Tongda Hnyav kev lag luam, LP saw crusher los yog tawb crusher, siv conveyor, thiab lwm yam.

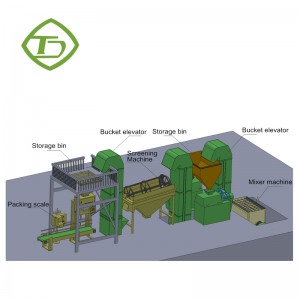

- Lub proportioning system ntawm proportioning system muaj xws li hluav taws xob proportioning system, disc feeder thiab vibrating screen, uas muaj peev xwm configure 6-8 hom ntawm raw khoom nyob rau hauv ib lub sij hawm.

- Kev sib xyaw ua ke ntawm kev sib xyaw ua ke muaj cov kab rov tav tov khoom lossis cov khoom sib xyaw disc, lub vibrating npo, txav tau siv conveyor, thiab lwm yam.

- Cov khoom siv granulator xaiv tau, cov txheej txheem granulator ntawm cov txheej txheem tsim cov organic chiv, xav tau cov khoom siv granulator.Cov khoom siv granulator xaiv muaj xws li: compound fertilizer rau cov menyuam extruder granulator, disc granulator, ca zaj duab xis granulator, bio-organic chiv spherical granulator, organic chiv granulator, nruas granulator, thrower, compound fertilizer granulator, thiab lwm yam.

- Lub tshuab ua kom txias thiab ziab ntawm lub tshuab ua kom txias thiab ziab tuaj yeem siv rau hauv lub tshuab ziab khaub ncaws, lub nruas txias thiab lwm yam khoom siv rau kev ziab thiab txias.

- Kev tshuaj ntsuam xyuas qhov system feem ntau ua tiav los ntawm lub tshuab ntsuas lub nruas, uas tuaj yeem teeb tsa lub tshuab tshuaj ntsuam thawj zaug thiab lub tshuab ntsuas thib ob, kom cov khoom tiav ntawm cov khoom tiav siab dua thiab cov khoom zoo dua.

- Cov khoom ntim tiav tiav Cov khoom ntim khoom tiav feem ntau suav nrog cov khoom siv hluav taws xob ntim khoom ntim, tsev khaws khoom, tshuab xaws tsis siv neeg thiab lwm yam.Nyob rau hauv txoj kev no, tag nrho tsis siv neeg thiab tsis muaj kev cuam tshuam ntawm cov organic chiv ntau lawm kab tuaj yeem pom tau.